Smart Metrology Camera 350

The SMC 350 is a cost-effective extension of your processing machine with a contactless probing and measuring option without having to unclamp the workpiece. The recorded structures in the images can be measured on the corresponding system PC/laptop and can be further processed and archived for documentation purposes.

* Universal optical sensor for use in processing and measuring machines

* Compact, wireless measuring camera with high-resolution precision optics

* Optical probing and measurement in the field of view or in interaction with the axis measuring systems of the machine possible

* Intuitive operation of measurement and camera control functions via software

* Easy installation and portable use through battery operation

Technical specifications

Camera signal

Full-HD 1080 (1920 x 1080 Pixel), SONY-Sensor, 25 Frames/sec.

Video-out

HDMI, internal/external frame grabber for PC and laptop

Optical system

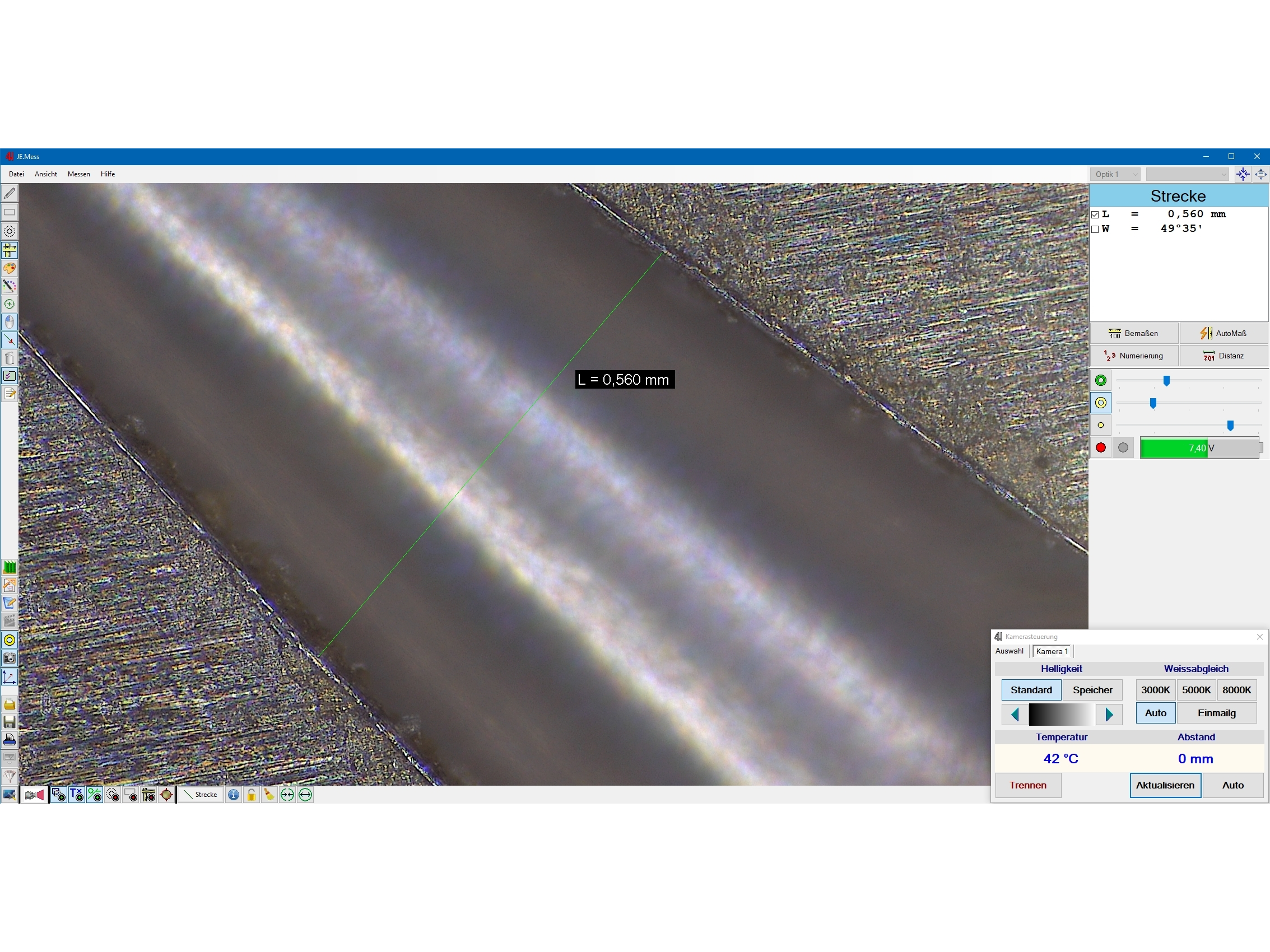

field of view approx. 1.1 mm x 0.65 mm, resolution approx. 0.5 μm/Px, 350x

Magnification related to 24″ monitor

Illumination

ring light white, ring light green, coaxial positioning spot red

all lights individually dimmable

Sensors

Distance sensor (collision warning)

Temperature sensor internal

Record format

Still image: JPEG, BMP

Video: windows-specific format ASF, 720p

Mechanical mounting

Cylinder (different diameters) or customer specific

Power supply

Operation with rechargeable battery, charge inductive 5V / 2A via

supplied charging pad/power supply

Battery life approx. 150 min/charge

Dimensions

approx. 140 mm x 100 mm x 75mm (without mounting solution)

Mass

approx. 1 kg plus device-specific mounting

Scope of delivery

SMC 350, charging module, video receiver, HDMI cable, BT-Controller,

Power supply, Software JE.SMC

NEU MACHEN: Bildbeispiele:

(klick zum Vergrößern)

Data sheet

Applications

- As an optical probe for non-contact probing of fragile ultra-fine structures, optical surfaces and soft materials

- Retrofitting of a measuring possibility for existing machines by specific adaptation systems and wireless operation

- Use on several machines with mechanical quick-change adapter (e.g. clamping mandrel or clamping guide)

- Measurement of geometric quantities using the JE.SMC software

- Documentation and measurement tasks in the field of mechanical and electronic production

- Creation of measurement reports for the verification of production parameters

Advantages

- individual device customization

- Full-HD resolution (1920 x 1080 pixels)

- ultra-fast image display due to low latency (live image)

- integrated search-spot enables quick finding of the measuring point

- 2 shifting colored LED ring lights for optimal illumination

- complete light and camera control from PC

- flexible use due to wireless design

- approx. 150 min working time under full load, increase by energy saving mode

- Image measurement and evaluation by supplied software JE.SMC

- Diverse measuring possibilities for geometric figures (incl. creation of measuring protocol)

Options

MAKE NEW Accessories

- Solder protection glass

- VT and IT series inspection tables

- Ball and Socket stages in different diameters